Simple Hardware for In-stream Data Loggers

Metal signposts, bolts, PVC pipe, epoxy, rock climbing anchors, and cable ties are the bread and butter of in-stream data logger systems. The goal is to create systems that are tough, waterproof, rust-resistant, safe, and reliable. The river will eventually eat and destroy everything, but how can we install sensors and dataloggers to get a little bit of life out of them? This blog post was put together to gather a list of resources for stream data logger installations. The primary focus here is on data loggers for stream temperature and water level (flow).

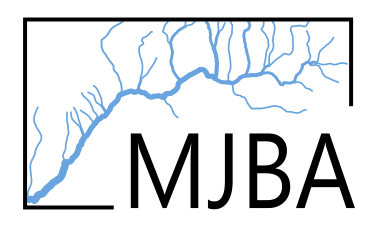

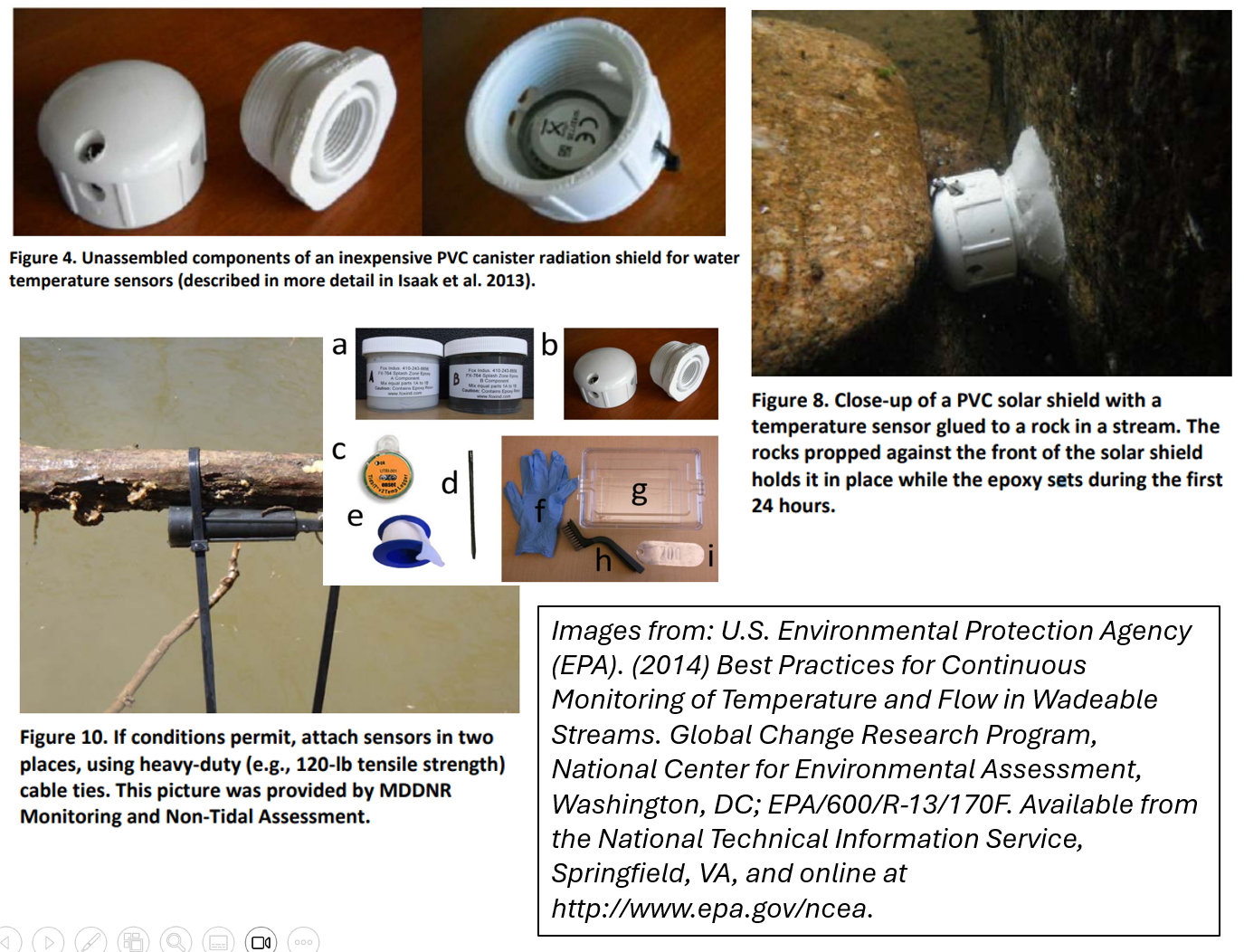

Stream temperature logger installations can be slightly simpler than installations for water level (stage) since subtle movement of the sensor is acceptable. A variety of methods have been used for stream temperature loggers including rebar, climbing bolt/chain and steel pipe as well as a novel method developed by Dan Isaak, Dona Horan, and Sherry Wollrab (2014) at US Forest Service/Rocky Mountain Research Station that strategically leverages PVC pipe end caps, underwater epoxy, and temperature tidbit loggers (see image below).

The authors recommend an epoxy product called “FX-764 Hydro-Ester® Splash Zone Epoxy from Fox Industries”. However, FX-764 is no longer in production and has been replaced by a new underwater epoxy called SeaShield SZ™ Underwater Epoxy (Underwater Splash Zone Epoxy Mastic). The SeaShield epoxy can be ordered from Denso Canada (technical data sheet).

Water level pressure logger installations can be a bit more complex since it's necessary for the logger to be placed firmly such that any movement is prevented. The following images show a few screen shots from report excepts (links below). Water level loggers are usually hosed within PVC or steel pipes and then attached to some form of anchoring system. Different systems are more/less appropriate for large systems vs small systems and high velocity vs low velocity environments.

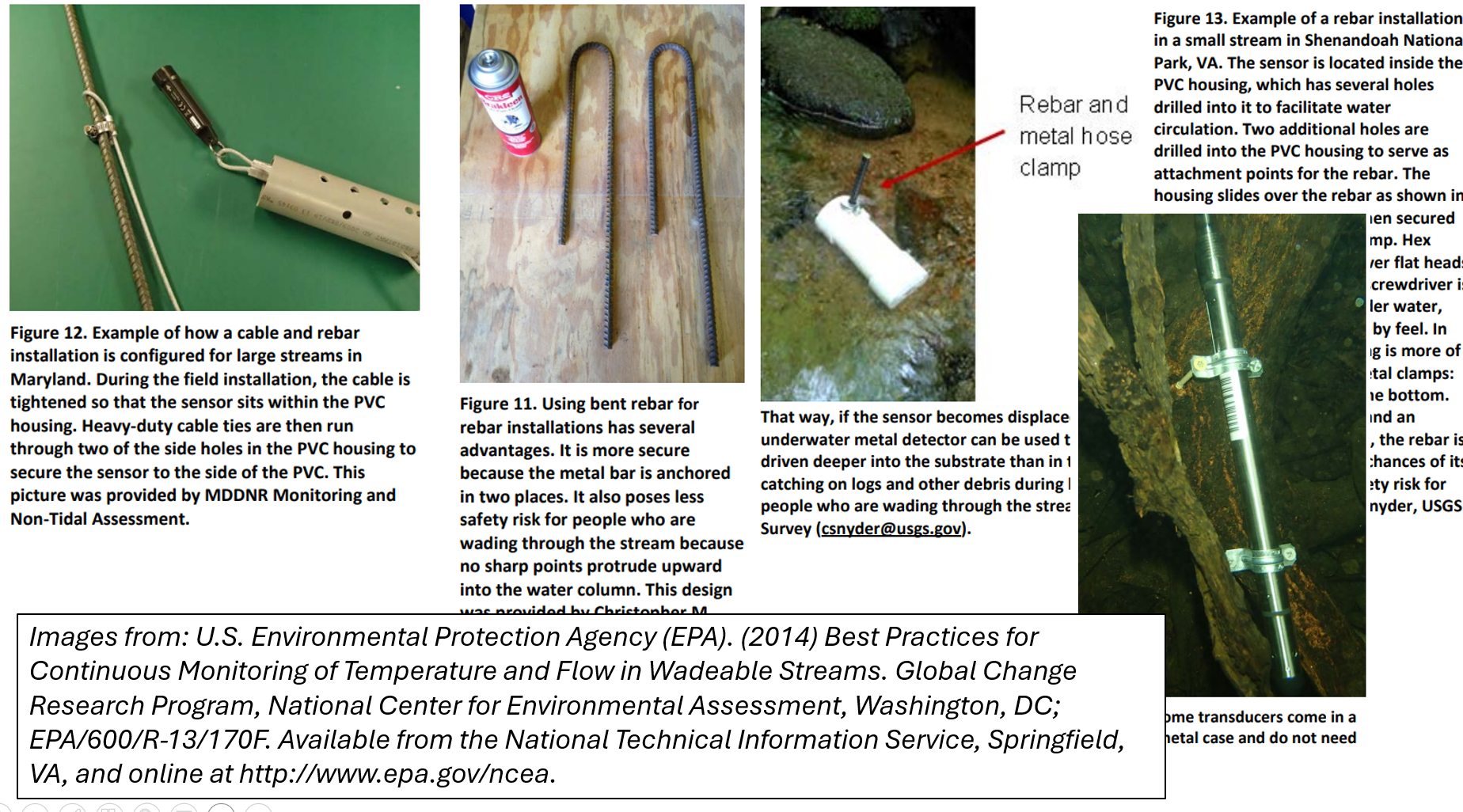

Many installations, like the setup featured on the Stroud Water Research Center EnviroDIY blog post, involve sliding a logger housing system over a piece of rebar anchored to the stream. Other setups involve bolting an anchor directly onto the downstream end of a large bolder and then attaching logger housing to the rock anchor (see method details described by Fogg et al 2020). The streambed rebar anchors are easier to install, but they are considered to be less secure than properly installed rock anchors. Unfortunately, rock anchors can only be installed during low flow conditions, or with highly specialized equipment.

Staff gauge installations tend to be quite a bit more obnoxious, as they (necessarily) must protrude above the water line at all flows. It’s most common for staff gauge installations to involve stream bed rebar anchors (example installation video) or rock anchor bolts (example installation video - images only).

References:

- U.S. Environmental Protection Agency (EPA). (2014) Best Practices for Continuous Monitoring of Temperature and Flow in Wadeable Streams. Global Change Research Program, National Center for Environmental Assessment, Washington, DC; EPA/600/R-13/170F. Available from the National Technical Information Service, Springfield, VA, and online at http://www.epa.gov/ncea [LINK].

- Fogg, S. K., O’Daniel, S. J., Poole, G. C., Reinhold, A. M., & Hyman, A. A. (2020). A simple, reliable method for long‐term, in‐stream data logger installation using rock‐climbing hardware. Methods in Ecology and Evolution, 11(5), 684-689. [LINK]

- 2022. EnviroDIY. Installing an EnviroDIY Monitoring Station. https://www.envirodiy.org/knowledge-base/installing-an-envirodiy-monitoring-station/. Stroud Water Research Center. Last updated on 2022-12-02.

- Isaak, Daniel J.; Horan, Dona L.; and Wollrab, Sherry P. 2013. A simple protocol using underwater epoxy to install annual temperature monitoring sites in rivers and streams. Gen. Tech. Rep. RMRS-GTR-314. Fort Collins, CO: U.S. Department of Agriculture, Forest Service, Rocky Mountain Research Station. 21 p. [LINK] | [VIDEO]

- DocumentDenso-SeaShield-SZ-Underwater-Epoxy.pdf (198.53 KB)